The correct construction of cavity trays is crucial to preventing water ingress. Cavity trays, including weep holes and stop ends, prevent the build-up of water within a cavity wall and allow the water to escape through the outer leaf.

This guidance is applicable to masonry cavity walls in buildings less than 18m in height.

In critical locations within low rise cavity masonry walls where the risk of water ingress is particularly high, the cavity tray detailing is complex and relies on a high level of workmanship, it is recommended that in a proprietary cavity tray system is installed.

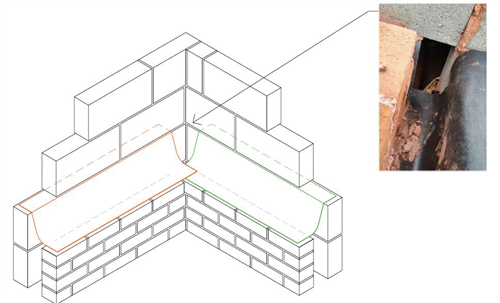

Figure 1: Incorrect installation at a corner junction

Figure 1 has been produced to give the photograph taken by one of our site surveyors some further context. In the photograph, you can see an attempt to form a cavity tray using a flexible type DPC around a corner. However, the end of each sheet could not be turned up at the corner intersection, resulting in a clear passage for moisture ingress to the cavity below. This is a common corner detail that many developers get wrong.

The construction of stepped cavity trays and cavity trays around corners relies on a high level of workmanship to install and work correctly.

As such, it is recommended that in low rise cavity masonry walls a proprietary cavity tray system should be used for all stepped abutments or lower storey abutments and where cavity trays continue around corners.

By using a propriety cavity tray system, the risk associated with forming cavity trays in these areas is reduced.

This also meets the recommendations of BS8215 Design and installation of damp proof course in masonry construction section 6.7 which states:

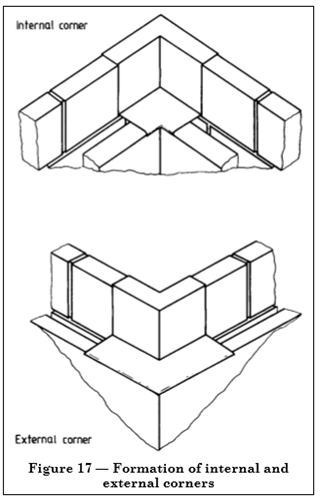

‘because changes of direction of a cavity tray are more complicated than joints and would involve complex bending and folding if fabricated on site, it is recommended that prefabricated corner units are used’.

The BS also reiterates the importance of ensuring the preformed trays are correctly sealed to the continuing trays.

Figure 2: Figure 17 taken from BS8215 demonstrating prefabricated trays used at corners

The use of preformed cavity trays reduces the risk in these areas, however it is still important that the cavity trays are the correct trays for the position and that the trays are positioned correctly in the wall with the bed joint raked out to allow installation of the flashing (see our article Horizontal Cavity Trays Over Horizontal Roof Abutments for further information).