Download a PDF version of this article.

This guidance provides information to designers, developers and surveyors to assist in meeting the functional requirements of the Premier Guarantee warranty Technical Manual where rainscreen cladding, brickwork, windows, doors and or curtain walling is proposed on a project covered by our warranty.

The purpose of site watertightness testing of newly‐constructed wall cladding and glazing, prior to practical completion, is to assess site workmanship for those joints that are formed and sealed on site and to check and test that the installed facade does not leak when subjected to such testing. This does not guarantee that the cladding or glazing will not leak in service, for example during severe or unusual weather conditions, but it gives confidence that the installed system has been properly constructed and to provide assurances it has been checked.

It is still contingent upon the specifier to select a façade system that is appropriate for the site exposure and has been subjected to an appropriate level of laboratory testing.

Curtain wall – A form of predominantly vertical facade which supports no load other than its own weight and the environmental and imposed forces which act upon it. A curtain wall should be tested off site in accordance with CWCT standards for systemised envelopes however, the interfaces between a unitised or stick system is prone to workmanship failure hence the requirement for site testing.

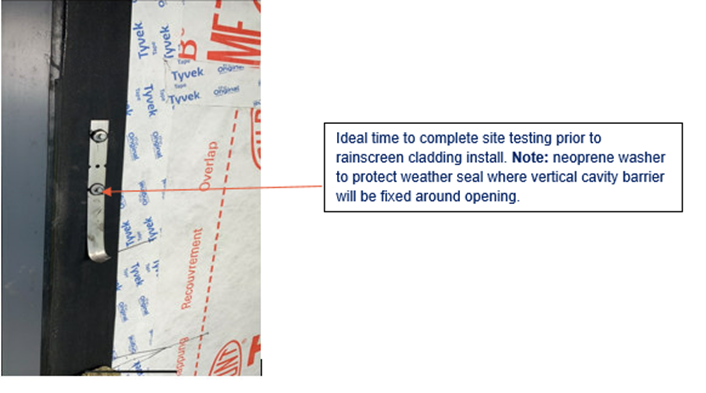

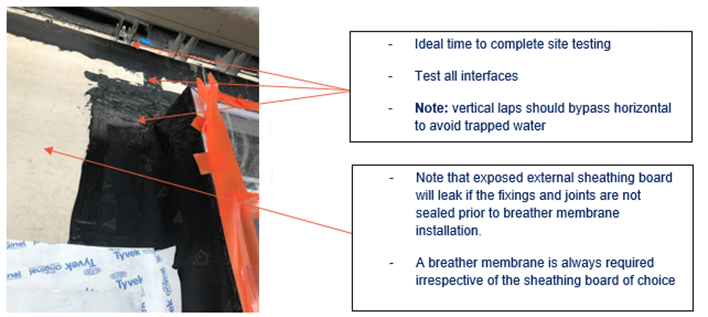

Rainscreen cladding – Is the attachment of an outer skin of rear-ventilated and drained cladding to a new or existing building. The system is a form of double-wall construction that uses an outer layer to keep out the rain and an inner supporting layer to provide thermal insulation, prevent excessive air leakage and carry the dead and live loads. Whilst the rainscreen will provide an element of protection from wind driven rain, it is important the back wall provides a weatherproof envelope, hence the need for site testing of the construction behind.

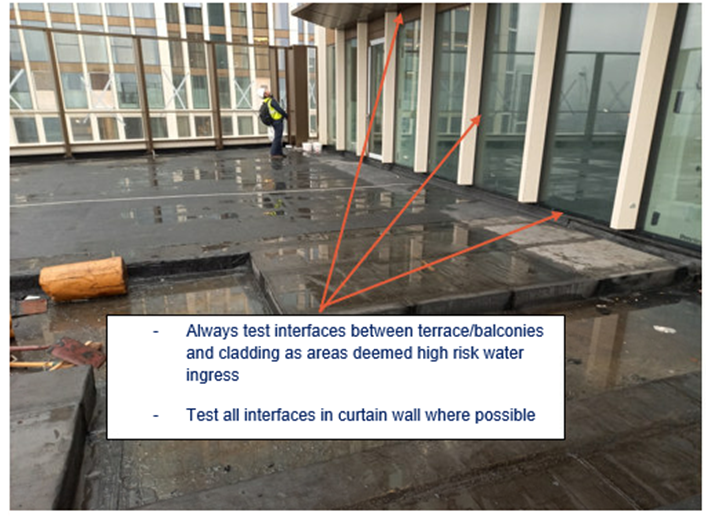

Site water testing is required for all cladding interfaces with an opening and to curtain wall elements (i.e. fixed joints around doors/windows/other penetrations). Test locations and method of testing to be submitted and approved by Premier Guarantee prior to testing. The site tests should constitute at least 5% by lengths of all joints the specifier considers to be critical.

Where more than one façade type is used, each façade type and each different interface must be tested and the sum of all testing should not be less than 5%. The locations of testing must be spread across each elevation and include the upper quarter of each building. It is critical the contractor provides marked up elevations clearly highlighting interface locations and test type which should be agreed with Premier Guarantee prior to commencement of testing.

The first completed area should always be tested for benchmarking purposes along with the last completed area. Testing to be in accordance with CWCT standard for systemised building envelopes and in accordance with CWCT Technical Notes 41, 95 & 102.

Site testing should always be carried out before internal finishes are applied, hence the need for areas, location and method of testing to be agreed as early as possible. Failure to allow for adequate inspection of internals will result in a failed test.

Penetrations and interfaces in the facade that are prone to risk of water ingress and should be tested include:

Note: the choice of the seal is important so it can deal with the wind load, water and vapour resistance, flexural and general movement etc. It is for these reasons EPDM seals are the preferred material.

Whilst a traditional brick facade provides an element of protection, all penetrations in the facade are still at risk of water ingress. Premier Guarantee require onsite water testing as outlined above. The site testing should be completed upon installation of weathering around penetrations and prior to the brick facade commencing. Failing this, CWCT TN 102 Part 16 option a) should be specified from the outset.

'a. (most severe, recommended) Step 1: sheet over the brick wall and tape across the window perimeter joint, tape over the window sash opening joint, and Hose Test the fixed joint around the glazing unit at full pressure. Step 2: untape the window sash opening joint, then test the opening joint using the Hose Test with the laboratory-calibrated water pressure. Step 3: unsheet the brickwork and remove the tape from the window perimeter joint, then apply the Spray Bar Test to the entire window installation and surrounding brickwork. This approach ensures that each type of joint is tested to the best method available.'

All on site testing should be carried out by UKAS accredited testing organisation with evidence of current membership provided.

Hose Pipe:

Hose Testing (CWCT Section 9, AAMA 501.2-09) at full water pressure (220±20 kPa)

Most systems that have passed a laboratory static watertightness test at 600 Pa, including many with opening joints, should pass an onsite hose test at full water pressure so long as the details, materials and workmanship are the same as tested in the laboratory.

Spray Bar

Spray Bar Testing (CWCT section 10, BS EN 13051) +

*Spray bar testing is suitable for opening joints in curtain walling and sealed interfaces prior to rainscreen cladding being installed.

Testing:

Results:

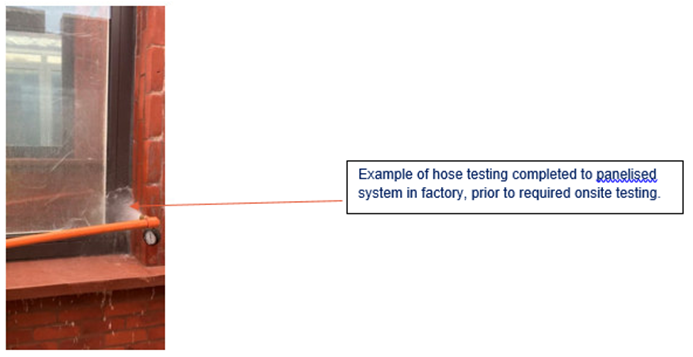

As part of Premier Guarantee acceptance of modular and panelised systems, they are required to complete off-site water testing within the factory which may include hose and spray bar testing or a combination of the both, depending on the specific system in question.

In addition to off-site testing, onsite water testing will always be required to test interfaces such as joints between modules/panels along with any penetrations in the modules as a result of any completed facade (rainscreen brackets, mechanical cavity barrier fixings through epdms etc). Onsite water testing can also determine any leaks due to damage to systems during the delivery and or erection process.

References (As of November 2022)

CWCT Standard test methods for building envelopes

CWCT Standard for systemised building envelopes Part 8

BS EN 13051 Curtain walling - Watertightness - Field test Without Air Pressure Using A Water Spray Bar, British Standards Institution

CWCT Technical Notes 24, 41, 101 & 102

Read more articles on InSite and sign up to receive our blog round-up.

Every care was taken to ensure the information in this article was correct at the time of publication (March 2023). Guidance provided does not replace the reader’s professional judgement and any construction project should comply with the relevant Building Regulations or applicable technical standards. For the most up to date Premier Guarantee technical guidance please refer to your Risk Management Surveyor and the latest version of the Premier Guarantee Technical Manual.

Ref: MK-3511